Author: Associate Vice President, Analytics and Data Strategy, Quantzig.

The modern business landscape is characterized by rapid technological advancements, shifting consumer preferences, and increased expectations for timely delivery. These factors, combined with political and economic instability, create an environment where companies must navigate an ever-growing volume of demand and supply variability. This variability can lead to imbalanced inventory levels, stockouts, or excess inventory, making it crucial for businesses to develop effective strategies for managing these fluctuations.

The complexity of global supply chains further compounds these challenges. Organizations must navigate intricate networks of suppliers, distributors, and logistics partners across different countries, all while managing additional risks such as geopolitical uncertainties, regulatory compliance, and cultural differences. These complexities can significantly impact the efficiency, cost, and reliability of the overall supply chain process, making it essential for businesses to adopt robust and agile systems for demand forecasting, production planning, and inventory management.

Book a demo to experience the meaningful insights we derive from data through our ai analytics tools and platform capabilities. Schedule a demo today!

Request a Free DemoTable of Contents

Why is Supply Chain Management Embracing Artificial Intelligence?

Supply chains face increasing complexity, prompting a shift toward AI solutions:

Embracing AI requires advanced technology but promises significant long-term advantages in the evolving global market.

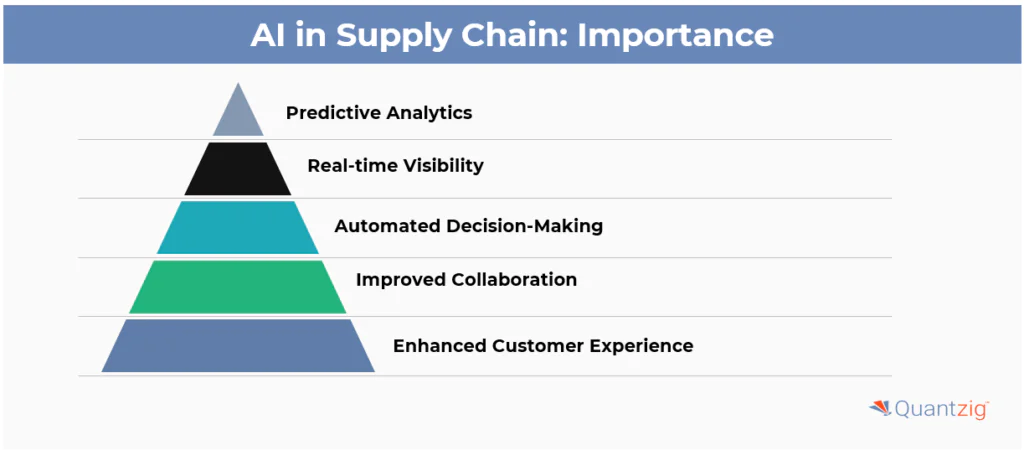

Importance of AI Supply Chain

Artificial intelligence (AI) is transforming industries by driving efficiency, lowering costs, and improving visibility. In supply chain management, AI-Powered Supply Chain Solutions are essential for optimizing logistics, predicting demand, and streamlining operations. Below are key points that highlight the significance of Artificial Intelligence in Supply Chain management:

- AI Supply Chain Visibility enhances transparency, offering real-time insights across operations.

- Predictive Analytics in Supply Chains helps anticipate demand and make informed decisions.

- Supply Chain Transparency with AI ensures a seamless flow of information, fostering better collaboration.

- AI for Supply Chain Optimization drives efficiency by automating tasks and optimizing processes.

- AI-Driven Supply Chain Insights provide actionable data to enhance decision-making.

These innovations enable Intelligent Supply Chain Management with a focus on Real-Time Supply Chain Visibility and operational efficiency.

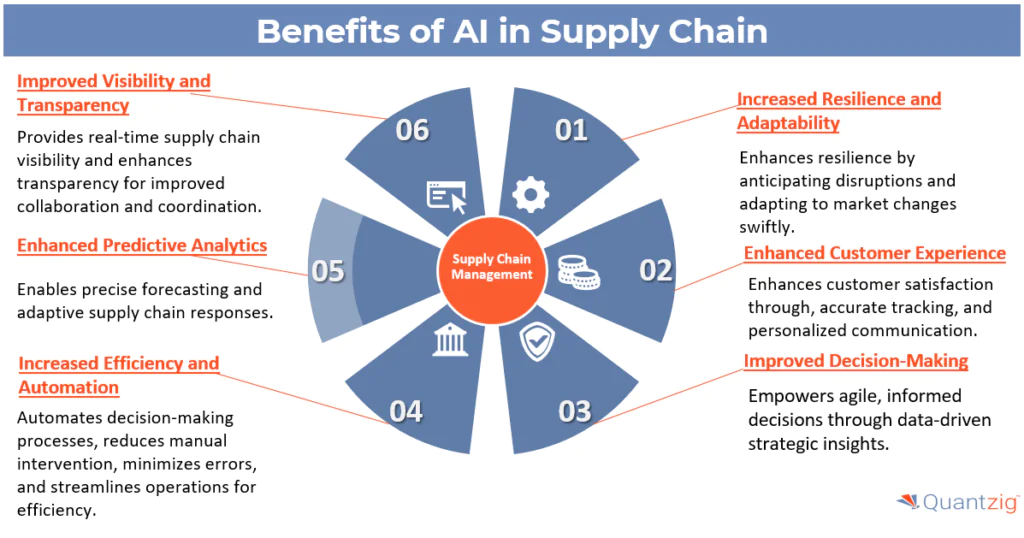

Benefits of Artificial Intelligence in Supply Chain Management

The integration of artificial intelligence (AI) in supply chain management can bring numerous benefits to businesses, including:

By leveraging these benefits, businesses can gain a competitive advantage, improve their supply chain performance, and drive long-term growth and success.

Challenges without AI in Supply Chain Management

The absence of AI in Logistics and Supply Chain Management Software can result in numerous challenges, including:

- Inefficient Operations: Without Supply Chain Automation AI, manual processes lead to inefficiencies, driving up costs and lowering productivity.

- Limited Visibility: A lack of IoT and AI in Supply Chains limits real-time tracking of shipments and inventory, causing delays and stockouts.

- Poor Predictive Analytics: Without Supply Chain Data Analytics and Machine Learning for Supply Chains, forecasting demand becomes challenging, leading to overstocking or understocking.

- Increased Risk: Without Supply Chain Risk Management with AI, manual processes increase the chances of human error, resulting in costly mistakes.

- Reduced Customer Satisfaction: Inefficient operations and lack of visibility hinder timely deliveries, negatively affecting customer satisfaction.

Incorporating Data-Driven Supply Chain Solutions, Supply Chain Digital Transformation, and Blockchain and AI in Supply Chain can address these issues, optimizing operations and enhancing efficiency.

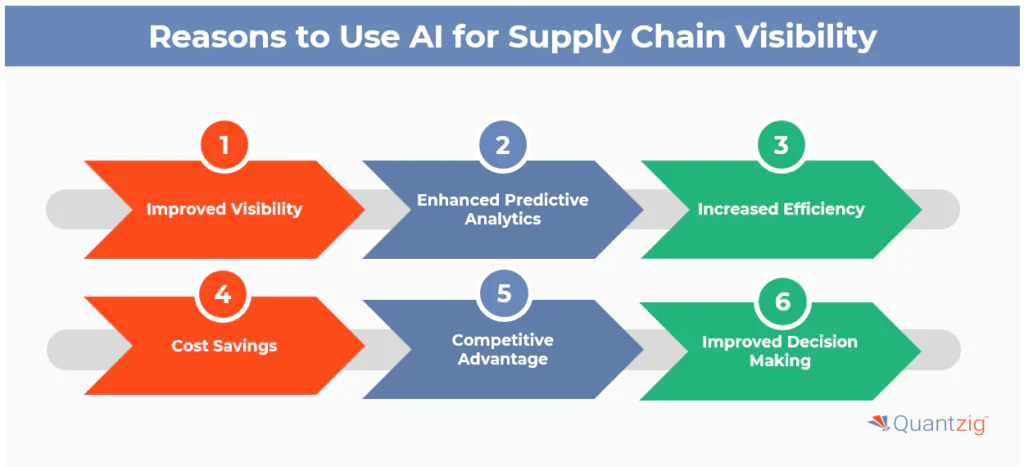

Why Should Your Business Use AI to Enhance Supply Chain Visibility?

Incorporating innovative technologies and AI-powered solutions, businesses optimize manufacturing processes and align with evolving consumer preferences. This transformation enhances inventory management systems and resource planning, fostering operational efficiency and strategic market adaptation. Implementing AI in supply chain management can bring numerous benefits to your business, including:

By leveraging these benefits, AI can help businesses achieve end-to-end supply chain visibility, leading to improved efficiency, reduced costs, and enhanced customer satisfaction.

Ways to Enhance Supply Chain Visibility with AI

Today, businesses leverage innovative technologies and AI-powered solutions to enhance manufacturing and cater to evolving consumer preferences. These advancements revolutionize inventory management systems and resource planning, ensuring efficient operations and proactive market readiness. To enhance supply chain visibility with AI, businesses can implement the following strategies:

- Implement IoT Sensors: IoT sensors can be used to track shipments and monitor inventory levels in real-time.

- Use Machine Learning Algorithms: Machine learning algorithms can be used to analyze data and predict demand, optimize inventory levels, and streamline operations.

- Integrate with ERP Systems: Integrating AI with ERP systems can provide real-time visibility into the supply chain and enable automated decision-making.

- Use Cloud-Based Solutions: Cloud-based solutions can provide scalability, flexibility, and cost savings, making it easier to implement AI in supply chain management.

- Collaborate with Suppliers: Collaborating with suppliers can help in improving visibility and streamlining operations by sharing data and best practices.

Common Supply Chain Challenges

Common supply chain challenges include:

- Inventory Management: Managing inventory levels effectively is crucial to ensuring timely delivery and minimizing stockouts.

- Logistics and Transportation: Ensuring timely and efficient logistics and transportation is critical to maintaining supply chain visibility.

- Supply Chain Disruptions: Disruptions can occur due to various reasons, including natural disasters, supplier insolvency, or equipment failure.

- Data Management: Managing data effectively is crucial to ensuring supply chain visibility and making informed decisions.

- Regulatory Compliance: Ensuring regulatory compliance is critical to maintaining supply chain visibility and avoiding costly penalties.

Quantzig is a leading provider of AI-driven supply chain solutions that empower businesses to optimize their operations, enhance visibility, and make data-driven decisions. With extensive expertise in cognitive computing and machine learning pipelines, Quantzig’s engineering services help companies harness the power of AI and ML to transform their supply chains.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a free pilotQuantzig’s Expertise in AI for Supply Chain

Quantzig’s AI solutions for supply chain management are designed to address the complexities and challenges that arise in today’s fast-paced business environment. By leveraging advanced analytics and AI-driven insights, Quantzig helps businesses:

- Optimize Inventory Management: AI-driven demand forecasting and inventory optimization enable businesses to reduce stockouts, minimize excess inventory, and improve fulfillment rates.

- Enhance Supply Chain Visibility: Real-time analytics and AI-powered dashboards provide actionable insights into market trends, demand patterns, and supplier performance, enabling proactive decision-making.

- Streamline Logistics and Route Planning: AI algorithms optimize transportation processes, reducing delivery times and improving customer satisfaction.

- Improve Supplier Collaboration: AI facilitates automated order processing, inventory control, and real-time tracking, ensuring timely deliveries and improved supplier relationships.

- Predictive Maintenance and Quality Control: AI-powered predictive solutions analytics enable early detection of potential equipment failures and optimize production schedules, reducing downtime and improving product quality.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start your free trialQuantzig’s Expertise in Similar Domain

Quantzig offers comprehensive AI in the supply chain solutions to enhance supply chain visibility and efficiency. Here are key services:

- Supply Chain Visibility: Gain advanced insights to manage inventory, reduce disruptions, and mitigate risks, leading to improved customer service and cost control.

- Inventory Management: Optimize inventory levels and forecast accuracy, as demonstrated by a U.S. manufacturer who reduced replenishment rates by 20% and improved forecast accuracy by 85%.

- Failure Mitigation: Address inbound and outbound delivery failures, with solutions that helped a sports goods manufacturer identify and rectify supply chain issues.

- Demand Forecasting: Improve demand management and forecasting through enhanced visibility, which facilitates better planning and response to market changes.

- Operational Efficiency: Streamline supply chain operations to reduce complexities, enhance response to disruptions, and increase overall efficiency, as seen in a client’s significant improvements.

- Customized Analytics Solutions: Tailored solutions for better order fulfillment and operational efficiency, including real-time visibility and innovative care models in the healthcare sector.

Quantzig’s supply chain analytics solutions enable businesses to gain continuous visibility into all supply chain processes, identify inefficiencies, reduce wastage, and optimize inventory for better customer satisfaction. With extensive expertise in cognitive computing and machine learning pipelines, Quantzig empowers businesses to harness the power of AI and ML to transform their supply chains and achieve competitive readiness, market excellence, and success.