Table of Contents

Introduction

In the ever-evolving landscape of modern business, the notion of a supply chain has witnessed a significant change in the dynamic realm of contemporary business, thus introducing the notion of Supply Chain 5.0. This innovative paradigm change is primarily fueled by technology and is motivated by an unwavering quest of resilience, sustainability, and efficiency. Supply chain intelligence is more than just increasing visibility. In this article, we’ll look at how supply chain intelligence, data analytics, AI, and cutting-edge technologies are changing the nature of supply chain management (SCM) in e-commerce.

In a world where uncertainty reigns supreme, understanding supply chain 5.0 principles and harnessing the power of intelligent logistics is essential for businesses to thrive in an era where agility and accuracy are king. With Quantzig’s innovative analytics dashboard solutions, you can unlock unparalleled insights and optimize your supply chain. Drive efficiency, reduce costs, and enhance decision-making capabilities to stay ahead in today’s competitive market landscape.

Request a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a free demo

Importance of Supply Chain Intelligence in Supply Chain 5.0

In the landscape of Supply Chain 5.0, characterized by the integration of robotics, IoT, AI, and big data, the role of supply chain intelligence becomes paramount for businesses striving to stay competitive and sustainable.

Navigating the New Age: Reinventing Supply Chain Strategies

In today’s hyper-competitive market ecosystems, supply chain strategies have emerged as critical pillars determining a company’s triumph or downfall. Modern consumers not only demand superior products but also seek traceability, transparency, stability, and swift delivery, especially in an era of diverse product interactions. This paradigm shift underscores the imperative for companies to proactively invest in robust, forward-thinking supply chain systems that are seamlessly connected. Such investments are indispensable for sustaining competitiveness, outpacing the relentless evolution of the corporate landscape, and meeting the high standards of service and reliability that modern consumers expect.

In this transformative journey, embracing robotics, IoT, AI, and big data becomes essential. These technologies enable Supply Chain 4.0, where advanced analytics, automation, and real-time planning drive efficiency and agility. Collaboration across stakeholders, including EV battery makers, fosters innovation and resilience in the face of disruptions. Furthermore, integrating the principles of the circular economy ensures sustainability and meets the ethical expectations of today’s consumers.

By prioritizing digitization, optimizing processes, and implementing robust risk management strategies, companies can future-proof their supply chains. This holistic approach not only satisfies current customer demands but also positions businesses to thrive in the ever-evolving marketplace, where meeting customer expectations is the new standard of excellence.

Enhanced Decision-making with Advanced Analytics:

Supply chain intelligence harnesses the power of big data and advanced analytics to provide businesses with actionable insights. By analyzing vast amounts of data generated by IoT devices and AI algorithms, companies can optimize processes, identify trends, and forecast demand with precision. This enables proactive decision-making, ensuring supply chain resilience and agility in the face of dynamic market conditions.

Risk Mitigation through Real-time Planning:

In an era of heightened supply chain security concerns, real-time planning facilitated by supply chain intelligence is critical for risk management. By continuously monitoring manufacturing, logistics, and procurement processes, businesses can swiftly identify and address potential disruptions, whether they stem from natural disasters, geopolitical tensions, or cybersecurity threats. This proactive approach minimizes downtime, reduces financial losses, and safeguards the integrity of the supply chain network.

Optimization of Machine Efficiency and Process:

Leveraging robotics and automation within Supply Chain 5.0 necessitates a deep understanding of the human-machine model. Supply chain intelligence enables businesses to optimize machine efficiency and process automation by analyzing performance metrics in real-time. By fine-tuning the interaction between humans and machines, companies can achieve greater productivity, lower costs, and enhanced safety standards, driving overall operational excellence.

Meeting Evolving Customer Expectations:

In an age where customer expectations are continually evolving, supply chain intelligence is instrumental in delivering on these demands. By embracing digitization and adopting a circular economy approach, businesses can create a future-proof supply chain that aligns with sustainability goals while catering to customer preferences for transparency and ethical sourcing. Collaboration with EV battery makers and other stakeholders fosters innovation and ensures that supply chains remain agile and responsive to changing market dynamics, ultimately enhancing customer satisfaction and loyalty.

In summary, supply chain intelligence serves as the cornerstone of Supply Chain 5.0, empowering businesses to make informed decisions, mitigate risks, optimize operations, and meet the evolving expectations of customers and stakeholders alike.

How Can Industry 5.0 Affect Supply Chain Transparency and Sustainability?

Industry 5.0, the latest paradigm in industrial evolution, promises to revolutionize businesses, strategies, and operations, deeply impacting supply chain transparency and sustainability. With a focus on robotics, IoT, AI, big data, and advanced analytics, Industry 5.0 places a premium on people and sustainability, driving the imperative for enhanced supply chain transparency. As consumer expectations rise, fueled by awareness of ethical and environmental concerns, businesses face mounting pressure to disclose the ethical, environmental, and social impacts of their supply chains, in alignment with circular economy principles and resilience strategies. Collaboration becomes paramount as stakeholders and investors scrutinize companies’ adherence to ESG objectives and regulatory standards, while risk management strategies must address supply chain security in the face of evolving threats.

Transparency fosters ethical collaborations, prompting EV battery makers to prioritize partnerships with suppliers demonstrating human rights and sustainability credentials. Likewise, manufacturers leverage real-time data insights to optimize processes, minimize waste, and enhance machine efficiency, ensuring compliance with ethical sourcing practices. By embracing digitization and real-time planning, businesses can proactively identify opportunities to reduce environmental footprint and mitigate risks, thereby future proofing their supply chains and meeting evolving customer expectations. In essence, Industry 5.0 heralds a new era of supply chain management, where transparency and sustainability are not just buzzwords, but fundamental principles driving business success.

Challenges in Implementing Supply Chain 5.0

In today’s digital age, the landscape of business operations has been reshaped, emphasizing the paramount importance of customer experience and satisfaction. As customer loyalty faces a decline across various sectors, companies are compelled to make substantial investments to sustain high levels of engagement, often at the expense of their profitability. In this dynamic environment, implementing Supply Chain 5.0 presents both opportunities and challenges. It demands a seamless integration of cutting-edge technologies and strategic foresight to navigate the complexities of modern supply chains. However, amidst the promises of enhanced efficiency and agility lie several hurdles that organizations must overcome to harness the full potential of Supply Chain 5.0.

Navigating the Digital Landscape:

Supply Chain 5.0 confronts the intricacies of today’s digital business ecosystem, where Robotics, Internet of Things (IoT), Artificial Intelligence (AI), and Big Data redefine operational paradigms. In this milieu, the imperative to meet heightened Customer Expectations amidst declining loyalty underscores the primacy of customer experience. Consequently, firms grapple with balancing investments in enhancing Customer Happiness against the bottom line, necessitating strategic allocation of resources.

Agility Amidst Complexity:

Implementing Supply Chain 5.0 demands a proactive stance towards managing Complexity and Uncertainty. The Fourth Industrial Revolution heralds an era where Industrial Revolutions intersect with advancements in EV Battery Makers and Circular Economy principles. This convergence amplifies the importance of Process Optimization, Data Management, and Advanced Analytics to streamline operations and fortify resilience. However, the challenge lies in crafting agile frameworks that integrate these elements seamlessly, ensuring adaptability amidst dynamic shifts.

Real-Time Responsiveness:

Supply Chain 5.0 hinges on Real-Time Planning and Continuous Learning Platforms to navigate disruptions effectively. Automation and Collaboration foster Machine Efficiency and facilitate swift responses to evolving scenarios. Yet, the complexity of Risk Management and Supply Chain Security underscores the need for robust Data Management and Supply Chain 4.0 principles. The ability to harness data swiftly and efficiently becomes paramount in driving resilience and maintaining operational continuity in the face of unforeseen events.

Future-Proofing Strategies:

Embracing Supply Chain 5.0 necessitates future-proofing strategies that anticipate and preempt challenges. As businesses strive for Sustainability and Longevity, they confront the imperative to build Future-Proof Supply Chains. This entails leveraging Digitization and Logistics innovations to enhance Machine Efficiency and bolster Customer Engagement. Nonetheless, the journey towards Supply Chain 5.0 demands a holistic approach that balances technological advancements with human expertise, fostering a symbiotic Human-Machine Model that embodies the ethos of resilience and adaptability.

While Supply Chain 5.0 holds immense potential for driving efficiency and innovation, its successful implementation is contingent upon overcoming multifaceted challenges. By addressing these hurdles proactively and leveraging the synergies of advanced technologies and strategic partnerships, businesses can embark on a transformative journey towards building resilient, future-proof supply chains that meet the evolving demands of customers and the dynamic nature of the market.

Benefits

In the ever-evolving landscape of global commerce, the advent of Supply Chain 5.0 brings forth a paradigm shift driven by technological innovation and strategic foresight. This transformative era harnesses the power of Supply Chain Intelligence (SCI), epitomized by advancements in Robotics, Artificial Intelligence, and the Internet of Things. As businesses navigate the complexities of labor shortages, global disruptions, and the imperatives of the Fifth Industrial Revolution, they are propelled towards redefining operational excellence and customer-centricity. In this discourse, we delve into the multifaceted benefits of Supply Chain Intelligence in Supply Chain 5.0, elucidating its pivotal role in fostering efficiency, transparency, sustainability, enhanced customer experience, and resilience.

Benefits of Supply Chain Intelligence in Supply Chain 5.0:

Increased Efficiency:

Supply Chain Intelligence in Supply Chain 5.0 revolutionizes operational dynamics by automating tasks, enhancing visibility, and facilitating data-driven decision-making. Through streamlined processes and reduced human error, operational efficiency is augmented, leading to cost efficiencies and heightened overall performance. This transformative approach, exemplified by solutions like OpTel’s Traceability Solutions, accelerates processes, ensuring swift adaptability amidst the dynamic contours of the modern business landscape.

Increased Transparency:

Supply Chain Intelligence engenders heightened transparency through real-time product tracking, traversing the entire supply chain spectrum. With enhanced visibility and traceability, quality assurance and safety standards are bolstered, instilling trust amongst stakeholders. Companies, inspired by initiatives like the GHG Protocol and EUDR compliance, leverage this transparency to foster customer trust and fortify relationships in an increasingly discerning marketplace.

Increased Sustainability:

Embracing Supply Chain Intelligence enables businesses to align procurement processes with sustainability objectives, thereby mitigating environmental impact. By integrating environmentally friendly products and practices, companies advance towards Environmental, Social, and Governance (ESG) goals, resonating with the ethos of the Circular Economy. Initiatives like the EU’s Carbon Border Adjustment Mechanism (CBAM) underscore the imperative of sustainability, guiding companies towards a more eco-conscious future.

Improved Customer Experience:

Supply Chain 5.0, underpinned by intelligence-driven workflows, culminates in optimized fulfillment processes, enhancing the customer experience. With swift delivery and product integrity, customer satisfaction and loyalty are augmented, amplifying brand value amidst the competitive milieu. Businesses, cognizant of the imperative of hyper-personalization and hyper-customization, leverage Supply Chain Intelligence to deliver tailored solutions that resonate with individual preferences, fostering enduring customer relationships.

Enhanced Resilience:

In an era punctuated by global disruptions and unforeseen challenges, Supply Chain Intelligence emerges as a bulwark of resilience. Through proactive contingency planning, real-time insights, and agile decision-making, businesses navigate disruptions with aplomb. Leaders like Ray Grady, CEO of Conexiom, exemplify the transformative potential of Supply Chain Intelligence in fortifying organizational resilience and ensuring operational continuity amidst turbulent times. By harnessing the synergies of workflow automation and human creativity, businesses pivot swiftly, emerging stronger in the face of adversity.

As we traverse the contours of Supply Chain 5.0, Supply Chain Intelligence emerges as the linchpin of operational excellence, sustainability, and customer-centricity. By embracing technological innovation and strategic foresight, businesses navigate the complexities of the modern business landscape with resilience and agility. The transformative potential of Supply Chain Intelligence, epitomized by its ability to enhance efficiency, transparency, sustainability, customer experience, and resilience, heralds a new dawn of operational excellence in the global marketplace.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a Free PilotSuccess Story

Client Details –

A Leading Spirit Manufacturing Company located in Europe.

Challenges faced by the Client

Inefficient Distribution Allocation

Despite its considerable revenue of around $1Bn, the famous European spirits manufacturer grappled with a distribution strategy challenge. Their allocation practices were predominantly rooted in partial cost calculations, a methodology that proved notably inefficient. This approach resulted in suboptimal distribution of goods, subsequently leading to cost inefficiencies and leakages across various points within the supply chain.

Complex Mix of Distribution Partners

Additionally, the client faced the complexity of managing a diverse array of distribution partners, encompassing both the company’s in-house fleet and third-party logistics (3PL) vendors.

Solutions Offered by Quantzig

- In the initial phase, Quantzig established a comprehensive framework to accurately assess the total shipment costs for in-house deliveries, providing the client with a clear understanding of their distribution expenses.

- Subsequently, leveraging data from the client’s delivery management system, Quantzig effectively prioritized deliveries and identified opportunities for order consolidation. To enhance decision-making regarding the use of the company’s own fleet versus third-party logistics (3PL), a comparative platform was developed. For in-house deliveries, advanced order dicing algorithms were employed to determine the most cost-effective delivery routes, ultimately optimizing the efficiency of their distribution processes.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

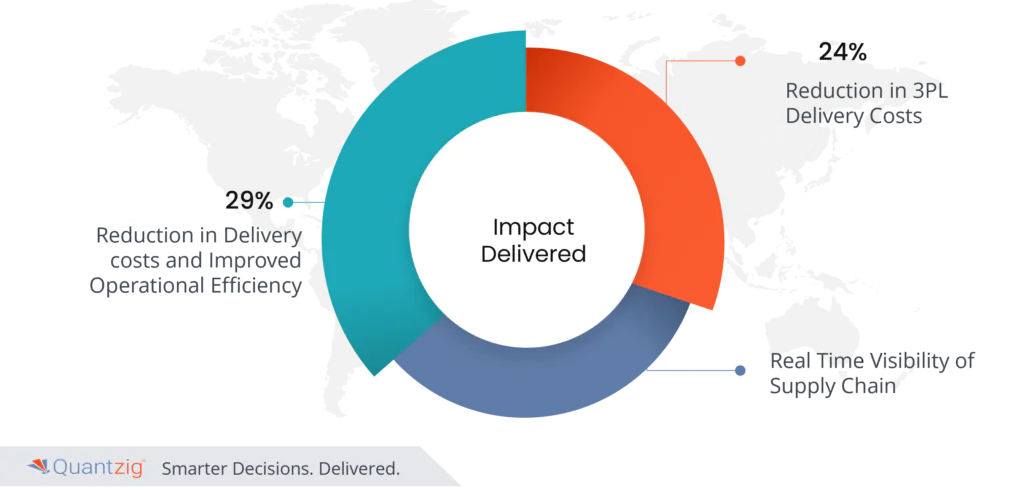

Start your Free TrailImpact Delivered

- 29% Reduction in Delivery costs and Improved Operational Efficiency – The impact of the transformation initiative was striking, featuring a significant 29% reduction in the client’s total delivery costs. This marked cost reduction not only bolstered the company’s financial performance but also streamlined its overall operational efficiency.

- 24% Reduction in 3PL Delivery Costs – The cost associated with third-party logistics (3PL) deliveries witnessed an impressive decrease of 24%, highlighting the tangible benefits derived from the optimized supply chain approach.

- Real Time Visibility of Supply Chain – The incorporation of advanced supply chain intelligence granted the client near real-time visibility into the complexities of their supply chain. This newfound transparency empowered the company to make more informed and agile decisions, ultimately enhancing their overall supply chain management and positioning them as a competitive force in the ever-evolving landscape of Supply Chain 5.0.

Conclusion

To conclusion, supply chain intelligence in supply chain 5.0 is the foundation of today’s business success. Supply Chain Intelligence helps businesses become more efficient, more transparent, more sustainable, better for their customers, and more resilient. It’s no longer an option, it’s a necessity. In today’s ever-evolving marketplace, embracing Supply Chain Intelligence isn’t an option; it’s an imperative. As businesses embrace Supply Chain Intelligence, they open the door to increased competitiveness and a brighter future.