Table of Contents

What You’ll Find in this Case Study:

- About the Client

- Industry Overview

- Demand Forecasting Efficiency Business Challenge

- Demand Forecasting Efficiency Solution and the Business Impact

- Demand Forecasting Efficiency Solution Insights

What’s the importance of demand forecasting in supply chain planning?

Demand forecasting plays a pivotal role in the landscape of supply chain planning, influencing decisions across various stages of the process. Here are five crucial reasons why demand forecasting holds paramount importance:

- Enhanced Customer Satisfaction: At the heart of supply chain planning lies the objective of meeting customer demands efficiently and effectively. Demand forecasting allows the planners to anticipate customer requirements accurately, ensuring that products are available when and where they are needed. By aligning production, inventory, and distribution with anticipated demand, businesses can minimize stockouts, backorders, and delays, thereby enhancing customer satisfaction levels.

- Optimized Resource Allocation: Supply chain planners rely on demand forecasts to allocate resources judiciously. Whether it’s raw materials, production capacities, or transportation assets, accurate forecasts enable efficient resource allocation, reducing waste and optimizing operational costs. By aligning resource allocation with expected demand patterns, businesses can maintain lean inventories, streamline production processes, and maximize utilization rates, thereby enhancing overall efficiency.

- Improved Inventory Management: Effective demand forecasting serves as the cornerstone of inventory management strategies. By providing insights into future demand trends, forecasts enable businesses to maintain optimal inventory levels, minimizing excess inventory while ensuring product availability. This proactive approach to inventory management helps mitigate overstock situations, reduce carrying costs, and minimize the risk of obsolescence, thereby enhancing inventory turnover rates and improving overall financial performance.

- Strategic Decision-Making: Demand forecasts serve as valuable inputs for strategic decision-making within the supply chain. By anticipating future demand dynamics, businesses can make informed decisions regarding production planning, capacity expansion, supplier relationships, and market positioning. Whether it’s identifying emerging trends, mitigating risks, or capitalizing on market opportunities, accurate demand forecasts empower supply chain planners to make proactive and data-driven decisions, thereby enhancing the agility and resilience of the supply chain.

- Effective Supply Chain Performance Management: Demand forecasting facilitates the establishment and monitoring of key performance indicators (KPIs) within the supply chain. By comparing actual demand against forecasted projections, businesses can evaluate the accuracy of their forecasts and identify areas for improvement. This continuous performance monitoring enables the planners to fine-tune forecasting models, refine inventory policies, and optimize supply chain processes iteratively. By fostering a culture of continuous improvement, demand forecasting contributes to the ongoing optimization of performance, driving operational excellence and competitive advantage.

What supply chain KPIs inform demand forecasting?

Key Performance Indicators (KPIs) play a critical role in informing demand forecasting processes, providing valuable insights into the efficiency, effectiveness, and overall performance of the supply chain. Here are five key KPIs that directly influence demand forecasting:

- Forecast Accuracy Rate: It measures the degree of alignment between forecasted demand and actual demand. This KPI evaluates the reliability and precision of demand forecasting models, highlighting areas where forecasts may be overestimating or underestimating demand. By monitoring forecast accuracy, planners can identify and address discrepancies, refine forecasting methodologies, and improve the overall reliability of demand forecasts. A high forecast accuracy rate enables businesses to optimize inventory levels, minimize stockouts, and enhance customer satisfaction by ensuring product availability.

- Inventory Turnover Ratio: It reflects the efficiency with which inventory is managed and converted into sales within a given period. This KPI compares the cost of goods sold to the average inventory level, indicating how quickly inventory is replenished and utilized. A high inventory turnover ratio suggests that products are moving rapidly through the supply chain, minimizing holding costs and reducing the risk of overstock situations. By monitoring inventory turnover, planners can assess demand patterns, adjust stocking levels accordingly, and optimize inventory management strategies to align with fluctuating customer requirements and market dynamics.

- Customer Fill Rate: The customer fill rate measures the percentage of customer orders that are fulfilled from available inventory within a specified timeframe. This KPI reflects the ability of the supply chain to meet customer demands promptly and accurately. By analyzing customer fill rates, planners can evaluate the effectiveness of inventory planning, replenishment processes, and distribution networks. Maintaining high customer fill rates is essential for enhancing customer satisfaction, fostering loyalty, and gaining a competitive edge in the marketplace. By identifying factors contributing to order fulfillment delays or shortages, businesses can take proactive measures to improve supply chain responsiveness and meet evolving customer expectations.

- Lead Time Variability: It refers to the degree of fluctuation or inconsistency in the time it takes to fulfill customer orders from the point of order placement to delivery. This KPI assesses the reliability and predictability of supply chain lead times, including procurement, production, and transportation lead times. Variability in lead times can impact demand forecasting accuracy, as unpredictable lead times may result in delays or disruptions in product availability. By minimizing lead time variability through process optimization, supplier collaboration, and inventory buffers, planners can enhance forecast stability and ensure a more reliable fulfillment experience for customers.

- Perfect Order Rate: The perfect order rate measures the percentage of orders that are delivered to customers without any errors or defects, meeting all specified requirements in terms of quantity, quality, and delivery timing. This KPI evaluates the overall effectiveness and efficiency of the order fulfillment process, encompassing aspects such as order accuracy, on-time delivery, and condition of goods upon receipt. By striving to improve the perfect order rate, planners can identify and address root causes of order fulfillment discrepancies, such as inventory inaccuracies, transportation delays, or supplier issues. Enhancing the perfect order rate not only fosters customer satisfaction but also reduces costs associated with order errors, returns, and rework, ultimately driving greater operational excellence and competitiveness in the marketplace.

Book a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Book a free demoSupply chain demand forecasting techniques

Supply chain demand forecasting techniques encompass a diverse array of methodologies and approaches aimed at predicting future customer demand with accuracy and reliability. Here are five key demand forecasting techniques employed within supply chain management:

- Time Series Forecasting: Time series forecasting involves analyzing historical data to identify patterns and trends in demand over time. By leveraging historical sales data, businesses can develop statistical models, such as moving averages, exponential smoothing, or autoregressive integrated moving average (ARIMA), to project future demand. Time series forecasting techniques provide a systematic framework for capturing seasonality, trends, and other temporal patterns, enabling supply chain planners to make informed decisions regarding inventory replenishment, production scheduling, and resource allocation.

- Predictive Analytics: Predictive analytics harnesses advanced statistical modeling and machine learning algorithms to forecast future demand based on various data inputs, including customer demographics, market trends, and external factors. By leveraging techniques such as regression analysis, decision trees, and neural networks, predictive analytics can uncover complex relationships and drivers of demand, enabling more accurate and granular forecasting. By integrating predictive analytics into planning processes, businesses can anticipate demand fluctuations, identify emerging trends, and adapt their strategies dynamically to meet evolving customer requirements.

- Customer Segmentation: Customer segmentation involves categorizing customers into distinct groups based on shared characteristics, preferences, or behaviors. By segmenting customers effectively, businesses can tailor their demand forecasting strategies to different customer segments, accounting for unique demand patterns and preferences. Segmentation techniques, such as RFM (Recency, Frequency, Monetary) analysis or clustering algorithms, enable the planners to identify high-value customers, forecast demand at a micro-level, and customize marketing and inventory strategies to maximize profitability and customer satisfaction.

- Scenario Analysis: Scenario analysis entails simulating different future scenarios or hypothetical situations to assess their potential impact on demand. By considering various factors, such as changes in market dynamics, economic conditions, or disruptions, businesses can evaluate the resilience of their demand forecasting models and develop contingency plans to mitigate risks. Scenario analysis techniques, such as sensitivity analysis or Monte Carlo simulation, provide valuable insights into the range of possible outcomes and the likelihood of different scenarios, enabling planners to make proactive decisions and build agile and adaptive supply chains.

- Machine Learning Algorithms: Machine learning algorithms offer a powerful means of forecasting demand by automatically identifying patterns and relationships in large datasets. Techniques such as neural networks, random forests, and support vector machines can analyze vast amounts of data, including historical sales data, market trends, and external factors, to generate accurate demand forecasts. Machine learning algorithms excel at capturing nonlinear relationships and adapting to changing demand patterns, making them well-suited for dynamic and complex supply chain environments. By leveraging machine learning algorithms, businesses can enhance the accuracy, scalability, and responsiveness of their demand forecasting processes, driving improved inventory management, resource allocation, and customer satisfaction.

How to improve supply chain demand forecasting?

Improving supply chain demand forecasting is essential for enhancing operational efficiency, reducing costs, and meeting customer expectations. Here are five key strategies to enhance demand forecasting accuracy and effectiveness:

- Data Integration and Enrichment: Integrating diverse sources of data, including sales transactions, market trends, customer behavior, and external factors, can enrich the forecasting process and improve accuracy. By leveraging advanced analytics tools and technologies, businesses can integrate structured and unstructured data from internal and external sources, such as ERP systems, CRM databases, social media, and IoT sensors. Data enrichment techniques, such as data cleansing, normalization, and augmentation, enable planners to capture a comprehensive view of demand drivers and enhance the robustness of forecasting models. By ensuring data quality and relevance, organizations can make more informed decisions and generate more accurate demand forecasts.

- Collaborative Planning and Forecasting: Collaborative planning and forecasting involve engaging stakeholders across the supply chain, including suppliers, distributors, and customers, in the forecasting process. By fostering collaboration and information sharing, businesses can gain valuable insights into demand variability, market dynamics, and supply chain constraints. Collaborative forecasting techniques, such as demand sensing, consensus forecasting, and vendor-managed inventory (VMI), enable real-time collaboration and alignment of demand forecasts with actual market conditions. By leveraging collective intelligence and domain expertise, organizations can enhance the accuracy and responsiveness of demand forecasts, reduce lead times, and improve agility.

- Continuous Model Refinement: Demand forecasting models should be regularly reviewed, refined, and updated to reflect changes in market dynamics, customer preferences, and business conditions. By leveraging historical performance data and feedback mechanisms, supply chain planners can assess the accuracy and effectiveness of forecasting models and identify areas for improvement. Continuous model refinement involves experimenting with different algorithms, variables, and parameters to enhance forecasting accuracy and adaptability. Techniques such as machine learning, time series analysis, and predictive analytics enable automated model tuning and optimization, ensuring that forecasting models remain agile and responsive to evolving demand patterns.

- Demand Sensing and Real-Time Data Analytics: Demand sensing leverages real-time data analytics and sensing technologies to capture demand signals as they emerge, enabling more responsive and accurate demand forecasting. By integrating data from point-of-sale (POS) systems, social media, weather forecasts, and supply chain sensors, businesses can detect demand fluctuations and trends in near real-time. Demand sensing techniques, such as predictive analytics, pattern recognition, and sentiment analysis, enable planners to identify demand drivers, anticipate changes in customer behavior, and adjust forecasting models dynamically. By leveraging demand sensing capabilities, organizations can improve forecast accuracy, reduce forecasting errors, and enhance supply chain agility and resilience.

- Investment in Talent and Training: Investing in talent development and training programs is crucial for building a skilled workforce capable of effectively managing demand forecasting processes. Planners should receive training in statistical analysis, data science, and forecasting methodologies to enhance their analytical capabilities and domain expertise. Additionally, organizations should foster a culture of continuous learning and innovation, encouraging collaboration and knowledge sharing among supply chain professionals. By investing in talent development, organizations can build a team of skilled forecasters capable of leveraging advanced techniques and technologies to improve demand forecasting accuracy, drive operational excellence, and achieve strategic objectives.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a free pilotAbout the Client

Client: A distilled spirits manufacturer, Size: $1.5 billion in revenue, Area of engagement: supply chain analytic solutions

Industry Overview

Distilled spirits refer to an alcoholic beverage manufactured by distilling the mixture produced from alcoholic fermentation. The distillation process is majorly applied to increase the alcohol content by reducing the diluting components such as water. Major factors propelling the growth of this market include steadily growing adult and young demographic worldwide and increasing demand for alcoholic beverages among consumers. Additionally, the advanced distribution channel including outlets in airports, online sales, and separate counters for females is another factor, propelling the demand for alcoholic beverages, thereby, conferring a boost to the global distilled spirits market. Furthermore, new product development and the innovation plays an important role in the distilled spirits market as the demand for these products largely depends on changing preferences and tastes.

Demand Forecasting Efficiency Business Challenge

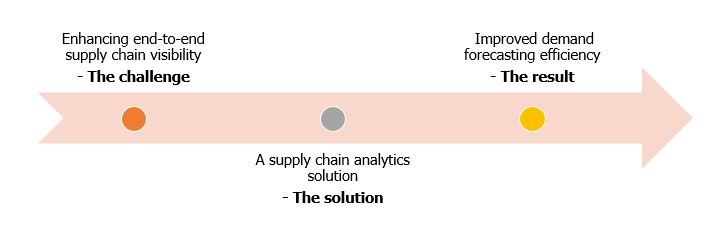

The client, a major in distilled spirits manufacturing with business units spread across the globe, wanted to develop an effective solution model to enhance end-to-end supply chain visibility to achieve high customer satisfaction during order fulfillment. Additionally, the client also wanted to develop an analytics solution for end-to-end supply chain visibility and identify the areas of optimization to ensure greater product delivery.

Demand Forecasting Efficiency Solution and the Business Impact

The distilled spirits manufacturer was able to overcome challenges that were affecting on-time and in-full delivery failure with the help of Quantzig’s supply chain analytic solutions. The client also identified key factors to ensure that the on-time and in-full delivery was greater than before. Moreover, a multi-source data integration facilitated an end-to-end visibility on supply journey of each product right from manufacturing to order delivery.

Demand Forecasting Efficiency Solution Insights

Quantzig’s supply chain analytics help firms in the food and beverage industry space to re-strategize their sourcing locations by analyzing the impact of supplier location and transit times on the design-to-market time of a product. Companies can also improve demand forecasting efficiency post automation of the sales-order process with the help of these solutions.

Our analysis of the global food and beverage industry shows that distilled spirits manufacturers are facing challenges in terms of:

- Altering consumer preferences: Today, consumers have become more informed and can gain access to a wide array of information in terms of the ingredients used in the final product offerings. Therefore, the altering preferences of the customers are compelling business providers to offer products that are in sync with the needs of the customers.

- High competition: The distilled spirits manufacturing industry is facing a growing competition with many companies offering innovative products. With the growing threat in the number of new entrants, establishments are facing the need to improve their production efficiency while promising the right quantity and quality at the right time.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start your free trial today