In the dynamic world of modern business, achieving a unified planning environment is essential for decision-making democratization and optimizing activities across operational and strategic levels. Model-driven demand planning applications, equipped with IBM Planning Analytics and integrated supply chain analytics software, are revolutionizing the way businesses balance customer demands with inventory management.

These applications not only enhance customer satisfaction but also drive profitability and efficiency gains. Our solutions, underpinned by advanced analytics and what-if scenario analysis, are designed to streamline operations, improve accuracy, and anticipate the evolving needs of customers in real-time. This article delves into how the best demand planning tools, leveraging AI-infused demand forecasts and predictive analytics, are transforming business operations by optimizing supply chain operations and strategic planning.

Book a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free DemoTable of Contents

Maximizing Business Potential with Demand Planning Automation

Demand Planning Automation is a cornerstone in the quest for achieving superior business goals in today’s competitive market. By integrating IBM Planning Analytics and leveraging the power of AI-infused demand forecasts, businesses can navigate the complexities of supply chain operations with unparalleled precision.

1. Real-time Supply Chain Visibility:

Automated demand planning offers end-to-end supply chain visibility, crucial for responsive decision-making. This visibility, coupled with predictive analytics, enables businesses to anticipate market trends, adapt to seasonality patterns, and respond proactively to potential disruptions.

2. Strategic Resource Allocation and Cost Efficiency:

Utilizing internal and external datasets, including weather forecasts and capacity requirements, automated demand planning helps in smart allocations of resources. This strategic planning ensures cost efficiency by reducing overstocks and avoiding stockouts, thus balancing inventory levels with customer demands.

3. Enhanced Customer Satisfaction Through Predictive Analytics:

The integration of advanced analytics tools in demand planning allows businesses to understand and predict customer needs accurately. This foresight ensures customer satisfaction by aligning production planning with market demands.

4. Opportunities for Growth with AI-Driven Insights:

AI-driven demand planning optimization opens avenues for businesses to identify new opportunities. It empowers enterprises to pivot quickly in response to market changes, leveraging AI-infused capabilities to uncover meaningful patterns and hidden trends.

5. Operational Efficiency with Integrated Business Planning:

Demand planning automation, supported by tools like Cubewise Supply Focus and predictive analytics, streamlines operations from procurement to warehousing. This integrated approach enhances operational efficiency, making businesses more agile and responsive to change.

By embracing automated demand planning, businesses can unlock a 360-degree view of their supply chain, driving revenue, reducing costs, and enhancing customer experiences. It’s not just a tool but a strategic asset, propelling businesses toward sustainable growth and a competitive edge in their respective industries.

Also Read: Maximizing Marketing Budgets with Campaign ROI Analysis

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start your Free Trial TodayNavigating Challenges in Demand Planning Automation Implementation

The journey towards successful demand planning automation is marked by potential challenges that businesses must adeptly navigate. Understanding and addressing these obstacles is key to unlocking the full potential of automated systems like IBM Planning Analytics and harnessing AI-infused demand forecasts.

1. Data Integration Complexities:

Integrating diverse internal and external datasets, including resource shortages and weather forecasts, can be a complex endeavor. Businesses need to ensure seamless data integration for accurate demand planning.

2. Balancing Customization and Scalability:

Implementing a demand planning system that is both customizable and scalable presents challenges. It requires careful planning to ensure the system can adapt to evolving business needs while maintaining operational efficiency.

3. Resource Allocation for Implementation:

The initial setup of demand planning automation demands significant time and resources. Businesses must strategically allocate these resources to ensure a smooth transition and effective implementation.

4. Overcoming Data Silos:

Ensuring consistent and accurate data flow between different departments, such as sales and planning teams, is critical. Overcoming data silos is essential for effective demand planning and avoiding delays in the planning process.

5. Addressing Forecasting Complexities:

Automated demand planning systems must handle the complexities of forecasting accurately, considering various factors like consumer behaviors, market trends, and external variables.

6. Ensuring Real-time Planning and Responsiveness:

Real-time planning and the ability to quickly pivot in response to market fluctuations are crucial. Businesses must ensure their automated demand planning system is equipped with advanced analytics for prompt and informed decision-making.

By overcoming these challenges, businesses can enhance their operational efficiency, optimize inventory management, and drive informed business decisions. Successfully implementing demand planning automation not only streamlines processes but also positions companies for sustainable growth and competitive advantage in their industry.

How Quantzig helped in Transforming Demand Planning with Automation – A Case Study

Discover how Quantzig’s expertise in demand planning optimization revolutionized the processes of a leading CPG company in the USA, showcasing the transformative power of automated systems like IBM Planning Analytics.

Client Details:

A prominent CPG company in the USA faced challenges in adapting to the dynamic market and customer demands. The company required a robust solution to streamline its demand planning process, ensuring effective inventory management and enhanced customer satisfaction.

Challenges:

The CPG company’s demand planning process was marred by prolonged completion times, manual coordination issues, and data inconsistencies. The traditional methods led to inefficiencies, delays, and a lack of real-time insights, creating a pressing need for an automated and integrated approach.

No infographic data found.

1. Transition to Digital Solutions:

Transitioning from traditional to digital demand planning processes, the company aimed to implement IBM Planning Analytics and leverage advanced analytics for real-time planning and decision-making.

2. Streamlining Operations with Automation:

By automating key components of the demand planning process, the company sought to enhance operational efficiency, precision in procurement, and effective inventory management.

3. Overcoming Data Silos and Integration Challenges:

Addressing the challenge of data silos, the company needed a centralized platform to ensure end-to-end supply chain visibility and seamless data integration across various internal and external datasets.

Solutions:

Quantzig’s automated demand planning solution delivered remarkable results:

1. Optimized Supply Chain Operations:

The implementation of AI-infused demand forecasts and predictive analytics streamlined the supply chain, enhancing responsiveness to market changes and customer needs.

2. Data-Driven Decision-Making:

Leveraging IBM Planning Analytics, the company gained a 360-degree view of its operations, enabling data-driven decisions and improving overall business performance.

3. Efficient Resource Management:

The automation facilitated smart allocations of resources, reducing excess inventory and ensuring demand-adjust imbalances were efficiently managed.

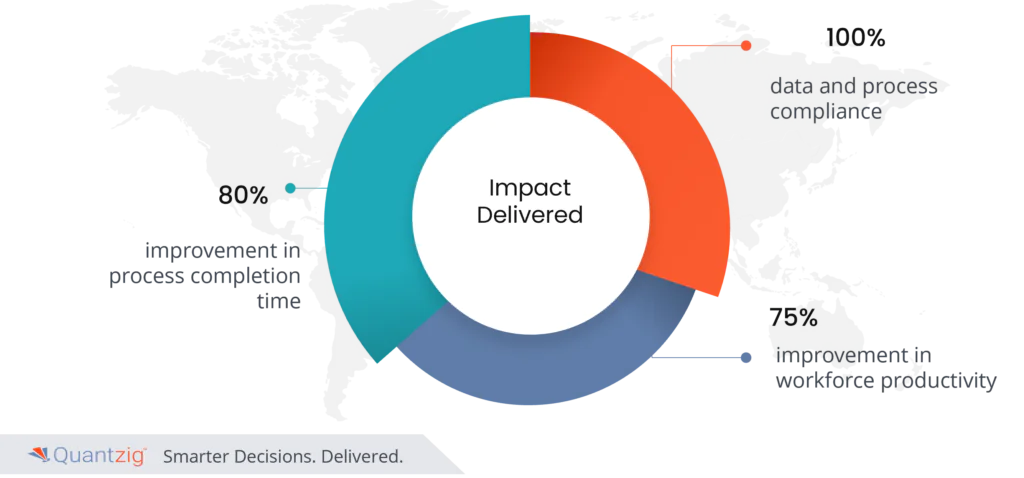

Impact Delivered:

The CPG company witnessed a transformative impact on its operations:

1. Significant Time Savings:

The automated process led to an 80% improvement in completion time, showcasing the efficiency gains from the new system.

2. Enhanced Data Accuracy and Compliance:

Achieving 100% data and process compliance, the company ensured accuracy and reliability in its demand planning.

3. Boost in Workforce Productivity:

With a 75% improvement in workforce productivity, the company optimized its human and material resources, leading to a more streamlined and efficient operation.

This success story exemplifies the powerful impact of automated demand planning in revolutionizing business processes, driving operational excellence, and enhancing customer satisfaction. It demonstrates how embracing advanced analytics and AI-infused forecasting can lead businesses toward a sustainable and competitive future.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a Free PilotCharacteristics of an Effective Demand Plan

An effective demand plan is comprehensive, data-driven, and adaptable. It integrates historical sales data, market trends, and predictive analytics to forecast future demand accurately. Key components include:

- Data Integration: Combining data from multiple sources such as sales, marketing, and supply chain.

- Advanced Analytics: Utilizing machine learning and AI to identify patterns and predict demand.

- Collaborative Planning: Engaging cross-functional teams to ensure alignment and buy-in.

- Scenario Planning: Preparing for various market conditions with contingency plans.

- Continuous Improvement: Regularly updating the plan based on real-time data and feedback.

Importance of Accurate Demand Planning

Accurate demand planning is crucial for several reasons:

- Optimized Inventory Levels: Prevents overstocking and stockouts, reducing holding costs and lost sales.

- Enhanced Customer Satisfaction: Ensures product availability, meeting customer expectations and fostering loyalty.

- Efficient Resource Allocation: Aligns production schedules and supply chain activities, minimizing waste and maximizing efficiency.

- Financial Performance: Supports better budgeting and financial planning, contributing to overall profitability.

- Competitive Advantage: Allows for agile responses to market changes, maintaining a competitive edge.

In summary, an effective demand plan is a strategic asset that drives operational efficiency and business success.

Ending Thought

An effective demand plan is a cornerstone of successful business operations. By leveraging comprehensive data integration, advanced analytics, and collaborative planning, organizations can accurately forecast demand and prepare for various market conditions. The importance of accurate demand planning cannot be overstated, as it directly impacts inventory management, customer satisfaction, resource allocation, financial performance, and competitive advantage. Companies that invest in refining their demand planning processes position themselves to respond agilely to market changes, ensuring sustained growth and profitability.