Quantzig’s advanced analytics solutions recently played a pivotal role in revolutionizing the operational efficiency of a prominent manufacturing giant grappling with inaccuracies in its forecasting processes. Recognizing that forecasting inaccuracies were driving up production costs and hindering profitability, the manufacturing client sought Quantzig’s expertise to implement data-driven strategies.

Leveraging cutting-edge predictive sentiment analysis and machine learning algorithms, Quantzig meticulously analyzed vast datasets encompassing historical sales, market trends, and production metrics. By identifying patterns and insights previously overlooked, we enabled the firm to optimize inventory levels, streamline production workflows, and enhance supply chain management.

The result was a substantial reduction in production costs, improved inventory turnover rates, and heightened operational agility. This transformative partnership underscores our commitment to empowering organizations with actionable insights, enabling them to navigate complex challenges and achieve sustainable growth in today’s fiercely competitive manufacturing landscape.

Table of Contents

Summary

Client: The case study revolves around a leading industrial manufacturer headquartered in the United States. With a robust global presence and an impressive annual revenue exceeding billions of dollars, the client operated a complex network of more than 20 manufacturing facilities and 70 warehouses worldwide.

Challenges: The client faced significant challenges stemming from forecast inaccuracy, which resulted in a combination of stockouts and excess inventory accumulation. These issues collectively contributed to significant financial losses, amounting to approximately 20% of their overall business revenue.

Solutions:

- Advanced demand forecasting:

To address the forecast inaccuracy challenge, the client collaborated with Quantzig, a renowned analytics and consulting firm. Quantzig undertook a comprehensive analysis of the demand signals of various SKUs, establishing an effective SKU classification framework. This classification allowed a deeper understanding of customer behavior and market trends.

- Machine Learning algorithms:

Quantzig enabled the client to leverage advanced machine learning algorithms, which analyzed the demand signals of individual SKUs. Multiple algorithms were deployed for each SKU, harnessing the power of predictive sentiment analysis techniques to enhance accuracy and robustness.

- Automated model evaluation:

Quantzig automated the process of calculating the Mean Absolute Percentage Error (MAPE) for each forecasting model. This automation eliminated manual calculations, streamlining the evaluation process. By objectively comparing the performance of different models, Quantzig helped select the best-fit model for each SKU.

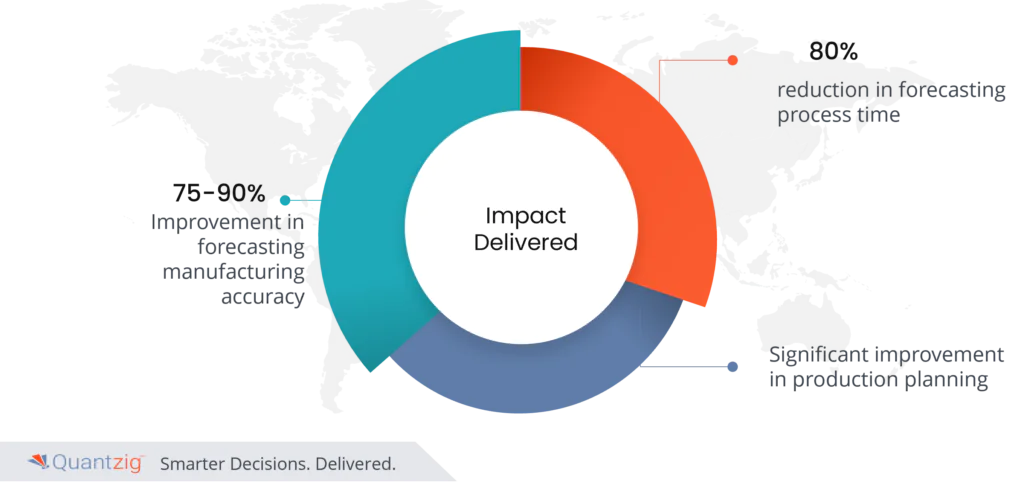

Impact Delivered

All of the above initiatives resulted in:

- 75-90% improvement in forecasting manufacturing accuracy

- 80% reduction in forecasting process time

- Significant improvement in production planning

Industry Overview

- The USA industrial manufacturing industry is a dynamic and integral part of the nation’s economy, accounting for a substantial portion of its Gross Domestic Product (GDP).

- Technological innovation is a hallmark of the USA manufacturing industry and it embraces cutting-edge technologies such as automation, robotics, the Internet of Things (IoT), artificial intelligence, and additive manufacturing to optimize processes and deliver innovative products.

About the Client

- Our recent client is a leading industrial manufacturer headquartered in the USA, with staggering revenue of over $4 billion. The client was facing the daunting challenge of a complex manufacturing process and was operating across 20 manufacturing facilities and 70 warehouses globally.

- The repercussions of inaccurate forecasting loomed large as the client grappled with stockouts and the detrimental impact of Inventory Holding costs (IHC), collectively resulting in a staggering 20% loss to their bottom line.

- Despite their significant market presence and revenue, the client’s profitability was under siege, necessitating urgent action to address the forecasting shortcomings and regain control over their operations.

- By unlocking the power of accurate demand forecasting, the client aimed to eliminate stockouts, optimize inventory levels, and maximize operational efficiency, ultimately securing their position as an industry leader in the highly competitive global market.

- The convergence of meticulous planning, advanced forecasting methodologies, forecasting in manufacturing process, and strategic decision-making would pave the way for the client to recapture lost revenue, streamline their manufacturing processes, and chart a path to sustainable growth.

Challenges

- The client’s predicament was further exacerbated by the ripple effects of forecast inaccuracy, leading to a cascading impact on various facets of their business operations. Not only did the flawed forecasting system strain their financial resources, but it also tarnished their brand reputation in the market. Customers, frustrated by inconsistent product availability, began to gravitate towards competitors, eroding the client’s hard-earned market share. This erosion in customer trust and loyalty posed a long-term threat, as rebuilding a damaged reputation often requires substantial time and resources.

- Additionally, the inefficiencies stemming from inaccurate demand forecasting had a domino effect on the client’s supply chain management. Suppliers faced challenges in aligning their production schedules with the erratic demand forecasts, leading to increased lead times, operational inefficiencies, and elevated costs. The disjointed synchronization between supply and demand further exacerbated the client’s inventory woes, amplifying the risk of obsolescence, wastage, and write-offs. Such inefficiencies not only strained relationships with suppliers but also diminished the overall operational resilience and adaptability of the client’s supply chain ecosystem.

- Recognizing the urgent need for a transformative shift, the client’s leadership team emphasized the importance of adopting a data-driven approach to forecasting. The objective was clear: leverage cutting-edge technologies and analytical tools to harness vast volumes of data, ranging from historical sales patterns and market trends to consumer behavior and macroeconomic indicators. By integrating these diverse data sets, the client aimed to cultivate a holistic view of demand dynamics, enabling more informed, agile, and proactive decision-making processes.

- The quest for a next generation forecasting solution was not merely about mitigating existing challenges; it was about fostering a culture of continuous improvement and innovation within the organization. The client envisioned a future where predictive sentiment analysis and machine learning algorithms would serve as the cornerstone of their strategic planning initiatives. By embracing these advanced manufacturing forecasting models, the client aimed to unlock new growth opportunities, optimize resource allocation, and cultivate a competitive edge in an increasingly volatile and unpredictable market landscape.

- To facilitate this transformative journey, the client established a cross-functional team comprising data scientists, supply chain experts, and business analysts. This multidisciplinary team was tasked with collaborating closely to identify gaps in the existing forecasting framework, evaluate potential technology solutions, and design a scalable and adaptable forecasting model tailored to the client’s unique business requirements. By fostering collaboration and knowledge sharing across various departments, the client aimed to cultivate a culture of innovation, agility, and data-driven decision-making at every organizational level.

In summary, the client’s pursuit of a groundbreaking manufacturing forecasting techniques was driven by a compelling need to rectify existing inefficiencies, mitigate financial losses, and foster sustainable growth. By embracing advanced analytics, machine learning algorithms, and predictive sentiment analysis techniques, the client aimed to elevate their demand forecasting capabilities, optimize inventory management, and enhance overall operational efficiency. Through strategic collaboration, innovation, and a relentless focus on continuous improvement, the client sought to redefine industry standards, cultivate customer loyalty, and position themselves for long-term success in an increasingly competitive marketplace.

Solutions

- To tackle the demand forecasting challenges head-on, Quantzig initiated the analysis of demand signals from a diverse range of SKUs, laying the foundation for a comprehensive understanding of their unique characteristics and patterns. Leveraging their expertise, Quantzig meticulously examined the demand signals of each SKU, unraveling the underlying factors that influence customer preferences, market trends, and seasonality. Through extensive data analysis and statistical modeling, Quantzig crafted an innovative SKU classification framework, enabling the client to categorize their product portfolio based on demand patterns, customer behavior, and other key variables.

- Building upon the foundation of demand signal analysis, Quantzig took it a step further by integrating advanced machine learning algorithms into the forecasting process, enabling a more sophisticated and data-driven approach. It helped the client to unlock deeper insights from the demand signals of various SKUs, uncovering hidden patterns and trends that traditional methods might overlook. Quantzig implemented a systematic approach by running multiple algorithms on each SKU, harnessing the collective power of diverse forecasting models to enhance accuracy and robustness.

- Taking automation to the next level, Quantzig implemented a streamlined process for calculating the Mean Absolute Percentage Error (MAPE) for each forecasting model, eliminating manual calculations and saving valuable time and resources. By automating the MAPE calculation, Quantzig ensured consistent and accurate evaluation of forecasting models for each SKU, enabling a more objective and data-driven selection process. Leveraging advanced algorithms and intelligent automation techniques, Quantzig seamlessly computed the MAPE for each model, providing the client with a standardized metric to compare and assess the performance of different forecasting approaches.

In conclusion, Quantzig’s expertise proved indispensable in assisting a leading manufacturing giant to mitigate the challenges posed by forecasting inaccuracies. Through advanced analytics and data-driven insights, we identified inefficiencies within the manufacturing forecasting techniques, facilitating strategic adjustments that culminated in a significant reduction in production costs. This successful collaboration underscores our ability to deliver actionable solutions tailored to specific industry challenges, highlighting the transformative impact of accurate forecasting on operational efficiency and profitability. As organizations continue to navigate complex landscapes, Quantzig remains a trusted partner, committed to driving measurable results and fostering sustainable growth through innovative analytics solutions.