Table of Contents

What You’ll Find in this Case Study:

- Highlights of the Case Study

- Game-Changing Material Requirement Planning Solutions for Food & Beverage Manufacturers

- Material Requirement Planning Challenges of the F&B Client

- Food & Beverage Material Requirement Planning Solutions

- Impact Analysis of Quantzig Material Requirement Planning System

- The Key Impacts of our Material Requirements Planning Solutions

- Key Outcomes

- Broad Perspective on the role of Material Requirement Planning in the F&B Industry

Highlights of the Case Study:

| Particulars | Description |

| Client | A leading manufacturer in the food and beverage industry |

| Business Challenge | To ensure accurate demand forecasts and better handling of raw materials and logistics |

| Impact | The unique features of Quantzig’s Material Requirement Planning system helped optimize the client’s inventory and output to align with demand forecasts. |

Game-Changing Material Requirement Planning Solutions for Food & Beverage Manufacturers

Raw materials used by F&B players are generally perishable and have a short life span. Thus, it is imperative to account for the freshness of the ingredients and better manage inventories. The (MRP) aids F&B players in planning for the forecasted demand and tuning their raw material purchases and production levels as per these forecasts. It helps them place accurate raw material orders at the right time.

Quantzig offers industry-specific MRP solutions that can enable players in the F&B industry to develop and execute an optimized plan for raw material procurement. Our high-level, real-time analytics provide our F&B clients with insights that aid in better decision-making.

How Material Requirements Planning (MRP) Works?

- Material Requirements Planning (MRP) is a crucial component of modern manufacturing (such as Process manufacturing, and discrete manufacturing), ensuring efficient production processes, optimal inventory levels, and streamlined supply chain management. MRP is a systematic approach that utilizes key elements such as the Bill of Materials (BOM), Master Production Schedule (MPS), and Inventory Status File (ISF) to drive production activities and meet customer demand effectively.

- At the core of MRP is the Bill of Materials (BOM), a comprehensive list detailing the raw materials, components, and sub-assemblies required to manufacture a finished product. Linked to the BOM is the Master Production Schedule (MPS), a strategic plan that outlines the production quantities and schedules for finished goods. This schedule serves as a guide for manufacturers, enabling them to align production with market demand and achieve revenue growth through the timely delivery of products.

- Inventory management is a critical aspect of MRP, addressing the balance between maintaining sufficient stock levels to meet customer demand while avoiding unnecessary carrying costs. MRP II, or Manufacturing Resource Planning, extends the capabilities of MRP by integrating additional factors such as factory workers, material and labor costs, and production delays. This integration enhances overall production efficiency and enables manufacturers to make informed decisions based on real-time data.

- To avoid disruptions in the supply chain, MRP utilizes a closed-loop system. This closed-loop MRP continuously assesses inventory status, making adjustments to production plans in response to changes in demand or supply chain dynamics. By managing inventory stockouts and optimizing lead times, MRP ensures that manufacturers can meet customer lead time expectations and maintain a competitive edge in the market.

Transform your manufacturing and supply chain processes with Quantzig’s cutting-edge Material Requirements Planning (MRP) solutions. Our tailored approach, leveraging advanced analytics and industry expertise, ensures optimal resource utilization, streamlined production, and enhanced overall efficiency. Elevate your operations with Quantzig’s MRP excellence for a future-ready manufacturing ecosystem. To understand how,

Request a free proposal- Automation plays a pivotal role in MRP, streamlining calculations and data management processes. Through the integration of Enterprise Resource Planning (ERP) systems, manufacturers can enhance data integrity and achieve a synchronized flow of information across various departments. This digital transformation supports economic order quantity calculations and aligns with the principles of renowned figures in manufacturing, such as Henry Ford and the Toyota Production System.

- The shift from traditional push production planning systems to pull systems is a hallmark of MRP’s evolution. The American Production and Inventory Control Society (APICS) has played a significant role in advancing these methodologies. Demand-driven material requirements planning (DDMRP) has emerged as a contemporary approach, integrating lean production principles and prioritizing customer-centric supply chain management.

Advantages and Disadvantages of MRP

Advantages of Material Requirements Planning (MRP):

• Optimized Production Planning:

MRP facilitates optimized production planning by utilizing the Bill of Materials (BOM) and Master Production Schedule (MPS) to ensure that manufacturers have the right materials and components available when needed. This strategic approach minimizes production delays, enhances efficiency, and supports revenue growth through timely product delivery.

• Efficient Inventory Management:

One of the key benefits of MRP is its ability to streamline inventory management. By maintaining an Inventory Status File (ISF) and continuously monitoring stock levels, manufacturers can prevent inventory stockouts and minimize carrying costs. This ensures a balanced approach to inventory that supports affordable consumer goods and sustainable revenue growth.

• Enhanced Supply Chain Visibility:

MRP provides enhanced visibility into the supply chain, allowing manufacturers to identify potential disruptions and proactively address issues. This contributes to the overall resilience of the supply chain management (SCM) process, aligning with the principles of closed-loop MRP and ensuring consistent product availability.

• Precision in Demand Planning:

MRP supports precise demand planning by considering factors such as lead time, dependent and independent demand, and customer lead time. This precision helps manufacturers align production with market demand, avoiding overproduction or shortages. The integration of advanced planning and scheduling (APS) software further enhances the accuracy of demand forecasts.

Disadvantages of Material Requirements Planning (MRP):

• Complexity and Implementation Challenges:

Implementing MRP systems can be complex, requiring significant time and resources. The need for accurate data, proper training, and robust data management practices poses challenges for some organizations. Ensuring data integrity and managing multilevel bill of materials in a dynamic production environment can be demanding.

• Dependency on Accurate Data:

The success of MRP hinges on the availability of accurate and up-to-date data. Inaccuracies in data, whether related to lead times, raw materials, or finished goods, can lead to errors in calculations and suboptimal decision-making. Maintaining data integrity is crucial to the effectiveness of MRP.

• Rigidity in Handling Changes:

MRP systems can be rigid in adapting to sudden changes in demand or production schedules. In situations where production delays or inventory stockouts occur due to unforeseen circumstances, MRP may struggle to quickly readjust plans. This lack of flexibility can impact the responsiveness of manufacturing operations.

• Costs and Resource Allocation:

The initial costs associated with implementing MRP systems, including software, training, and data management, can be significant. For some manufacturers, especially smaller businesses, these upfront costs may be prohibitive. Additionally, ongoing maintenance and updates can strain resources, impacting overall affordability for certain organizations.

Difference Between MRP and ERP:

Material Requirements Planning (MRP) and Enterprise Resource Planning (ERP) are both integral to the manufacturing and supply chain processes, yet they serve distinct purposes within an organization.

1. Scope and Functionality:

MRP primarily focuses on the planning and scheduling of materials and production processes. It utilizes the Bill of Materials (BOM) and Master Production Schedule (MPS) to ensure the availability of raw materials, optimize inventory levels, and streamline production.

ERP, on the other hand, is a broader system that integrates various business processes beyond materials and production. It encompasses financials, human resources, customer relationship management, and other organizational functions, providing a comprehensive solution for overall resource management.

2. Focus Area:

MRP is specifically geared towards managing and optimizing the production processes, ensuring that the right materials are available at the right time to meet demand.

ERP extends its reach beyond production to include finance, HR, and other areas, offering a holistic view of an organization’s resources and facilitating seamless communication between different departments.

3. Integration:

MRP systems are often standalone solutions focused on material and production planning. They may not integrate as extensively with other organizational functions.

ERP is designed to be an integrated solution, allowing real-time data sharing and collaboration across various departments. This integration enhances overall organizational efficiency.

4. Data Management:

MRP primarily deals with data related to materials, production schedules, and inventory. It requires accurate and timely data specific to these areas for effective planning.

ERP manages a broader set of data, including financials, HR records, customer information, and more. The accuracy and integration of this diverse data set are crucial for the success of ERP.

5. Complexity:

MRP systems are generally less complex than ERP systems, as they have a narrower focus on material and production planning.

ERP systems can be more complex due to their wide-ranging functionality, requiring comprehensive training and often involving a more extensive implementation process.

In summary, while MRP is a specialized tool for optimizing material and production planning, ERP serves as a comprehensive solution that integrates and manages a multitude of organizational functions beyond manufacturing.

The Challenges of the F&B Client

Our client, a major F&B player, faced severe demand fluctuations for its products due to several factors, such as adverse weather events and rapidly changing consumer trends, which led to volatile consumption patterns. The unpredictability of these factors meant that our client was either experiencing a shortage or a surplus of raw materials. Our client approached Quantzig to implement precise purchasing of raw materials based on accurate demand forecasts. It also sought to optimize its logistic infrastructure to ensure timely delivery of raw materials and finished products. In addition, it wanted us to track and trace the utilization of raw materials to safeguard use before expiration. Adequate visualization of inventory usage is critical in the F&B industry to minimize wastage, promote food safety, and thus adhere to stringent regulations.

Food & Beverage MRP Solutions

Our MRP software solutions are equipped with built-in forecasting tools that combine historical sales patterns and ongoing demand fluctuations, enabling our clients to estimate raw material requirements. Our MRP solutions represented an advance over the reorder point (ROP) process that our client previously utilized to restore inventory.

Our MRP is integrated with handheld barcode scanners that record and track raw materials’ expiration dates. We helped our client implement a first-expiry, first-out (FEFO) picking method through our solutions. Moreover, our client used our MRP system’s vendor modules and traceability features to compare anticipated lead times and actual delivery dates. In addition, it could flag anomalies such as incomplete and incorrect orders, which helped our client switch to better raw material suppliers.

Impact Analysis of Quantzig MRP system

Our client used the unique features of our MRP system, such as the time-phased manufacturing and purchasing plans, which helped optimize its inventory and output. The alignment of the entire manufacturing process with demand forecasts helped our client avoid shortages, which would have otherwise adversely impacted sales, revenues, and customer relationships.

Our solutions also provided our client with a complete view of the supply and demand for raw materials in the manufacturing process. It could create production instructions for its workforce and purchase an adequate number of raw materials based on inputs from the MRP interface.

The key impacts of our Material Requirements Planning solutions included the following:

- Reduced lead time required to procure raw materials from 30 days to 5-10 days

- Improved cash flow due to accurate planning of raw material purchasing

- Used historical sales data to forecast demand accurately throughout the year

Key Outcomes

The adoption of Quantzig’s MRP interface helped the client optimize its manufacturing process. Our system helped implement precise purchasing of raw materials based on accurate demand forecasts. It also streamlined the logistics base to ensure timely delivery of raw materials and finished products. The ability to track and trace the utilization of raw materials facilitated a reduction in wastage and adherence to food safety compliance regulations.

Broad Perspective on the role of Materials Requirement Planning in the F&B Industry:

The food and beverage industry are highly competitive, making it necessary for key players to leverage tools and resources to optimize the manufacturing process. Only a handful of solutions can handle businesses’ unique inventory management needs in the F&B industry, and even fewer partners can deliver the correct answers. Quantzig focuses on providing our clients in the F&B industry with new ways to improve their material planning, considering the fast-changing megatrends observed in the industry. Some of the significant trends in MRP technology include the following:

- Self-reporting inventory: MRP systems can now leverage the Internet-of-things (IoT), including smart devices and connected sensors, to deliver automation and self-reporting for materials resource planning.

- Mobile MRP solutions: Mobile-ready MRP solutions have become a norm as they offer inventory managers on-the-go access to data.

Key Takeaways

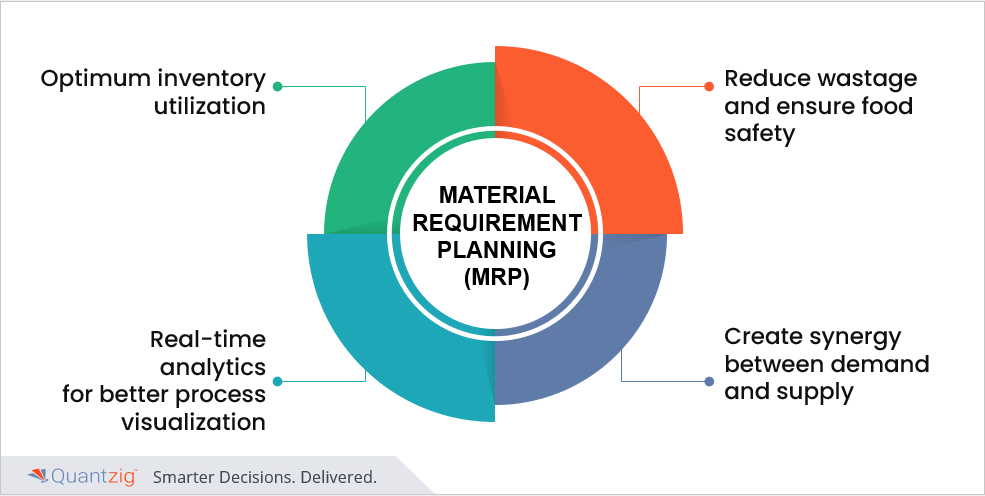

- Material requirement planning (MRP) tools are essential for optimum inventory utilization

- Tracking and tracing of raw materials to help to reduce wastage and maintain food safety

- MRP tools leverage business intelligence to forecast demand, analyze trends, and review order patterns

- Real-time analytics provide better visibility of the process

- Production planning tools create a synergy between demand and supply, which is essential in driving sales and revenues