Data mining and business intelligence go hand in hand and are often used together by businesses. Right from crime prevention agencies, mobile service providers, to major players in the e-commerce and retail industry, data mining has been adopted to build better business strategies and boost profit margins. In the case of supply chain management (SCM), data mining has emerged as a vital tool as it enables seamless integration of complex networks like inventory, production costs, and customer needs to accelerate core competencies.

Book a demo to experience the meaningful insights we derive from data through our analytical tools and platform capabilities. Schedule a demo today!

Request a Free Demo nowTable of Contents

What is Marketing Data Mining?

Marketing data mining is the process of extracting meaningful insights and patterns from large sets of marketing data. It helps businesses understand customer behavior, preferences, and trends to make informed marketing decisions. Techniques used in data mining include association analysis, clustering, and predictive modeling. Data sources for data mining can include customer transactions, website interactions, social media data, and demographic information. Data mining for marketing can be used to optimize advertising campaigns, personalize marketing messages, and improve overall customer satisfaction.

One crucial point which data mining puts into perspective is that it is not the quantity of the data, and rOne crucial point which data mining puts into perspective is that it is not the quantity of the data, and rather the quality which holds the key to the success of your enterprise. The standard way in which data mining works is:

- Assessing large sets of data and databases

- Using algorithms to discover clear patterns in the data

- Forecasting probable outcomes

- Building a reserve of actionable information

By allowing early detection of problems in the supply chain, anticipating wear and tear of the assets, and taking consumer demands into consideration, this technology facilitates manufacturers to have their production line on schedule.

Leveraging Data Mining to Tackle Common Supply Chain Challenges

Harnessing data is crucial for driving growth and staying competitive. Analytics and insights from data help businesses understand customer behavior, optimize marketing campaigns, and tailor strategies through customer segmentation analysis. Data mining, in particular, provides actionable intelligence for success.

- Enhanced Customer Segmentation: Quantzig’s data mining services enable businesses to extract valuable insights from large datasets. By analyzing demographics and purchasing behavior, companies can segment customers effectively and create personalized campaigns, boosting conversion rates and customer satisfaction.

- Dynamic Campaign Optimization: Quantzig leverages historical and real-time data to optimize marketing campaigns. We analyze performance across channels and messaging to refine strategies, maximize ROI and driving results.

- Predictive Modeling for Decision-Making: Using machine learning and predictive models, Quantzig helps businesses anticipate trends and adapt strategies. Our tools integrate with CRM systems, enabling personalized customer interactions and enhanced decision-making.

- Competitive Intelligence: Quantzig’s data mining for marketing uncovers competitive insights, helping businesses identify market gaps and stay ahead. Our analysis of trends, competitor activities, and consumer sentiment ensures informed strategic decisions and sustainable growth.

Investing in Quantzig’s data mining services empowers businesses to make informed, data-driven decisions that foster agility and long-term success.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start Your Free Trial now4 Types of Data Sources for Mining

Marketing data mining serves as a cornerstone for businesses seeking to unlock valuable insights, identify emerging trends, and refine their strategies to effectively reach their target audience. By analyzing diverse data sources ranging from campaign metrics to market research data, companies can gain a deeper understanding of customer behavior, optimize their segmentation approaches, and maximize the impact of their marketing efforts.

| Data Source | Key Insights |

|---|---|

| Customer Segmentation Analysis | Analyzing campaign data like click-through rates and conversion rates helps identify customer segments based on behavior and preferences. This allows for targeted marketing strategies to boost engagement and conversion. |

| Market Research Data | External data from industry reports, surveys, and social media trends provide insights into market dynamics and consumer preferences, enabling strategic decision-making and trend analysis for growth opportunities. |

| CRM Data Analysis | CRM systems offer rich customer data for predictive modeling, allowing businesses to forecast customer behavior and personalize interactions. This supports proactive marketing and customer relationship management. |

| Market Intelligence Gathering | Competitor analysis and industry reports provide valuable competitive insights. By analyzing market data, businesses can uncover trends and strategies to inform decision-making and stay ahead in the marketplace. |

By utilizing these diverse data sources, Quantzig enhances decision-making, optimizes marketing strategies, and drives sustainable growth.

How Does Data Mining Work?

Data mining is a process used by organizations to extract valuable insights from large datasets, enhancing supply chain operations and manufacturing processes. Data Mining in Market Research, on the other hand, involves several key steps:

- Data Collection: Gathering data from various sources such as inventory production, warehousing, and logistics systems.

- Data Cleaning: Ensuring data quality by removing errors and inconsistencies.

- Data Integration: Combining data from multiple sources to provide a comprehensive view.

- Data Transformation: Converting data into a suitable format for analysis.

- Data Analysis: Utilizing AI and statistical methods to identify patterns and trends.

- Evaluation: Assessing the findings against key performance indicators (KPIs) to ensure they are actionable and relevant.

- Deployment: Implementing the insights into practical applications such as demand forecasting, risk analysis, and inventory optimization.

Data scientists play a crucial role in this process, using advanced algorithms to uncover hidden patterns that drive process improvement and enhance supply chain management. This systematic approach helps organizations streamline operations and improve overall efficiency in lean manufacturing.

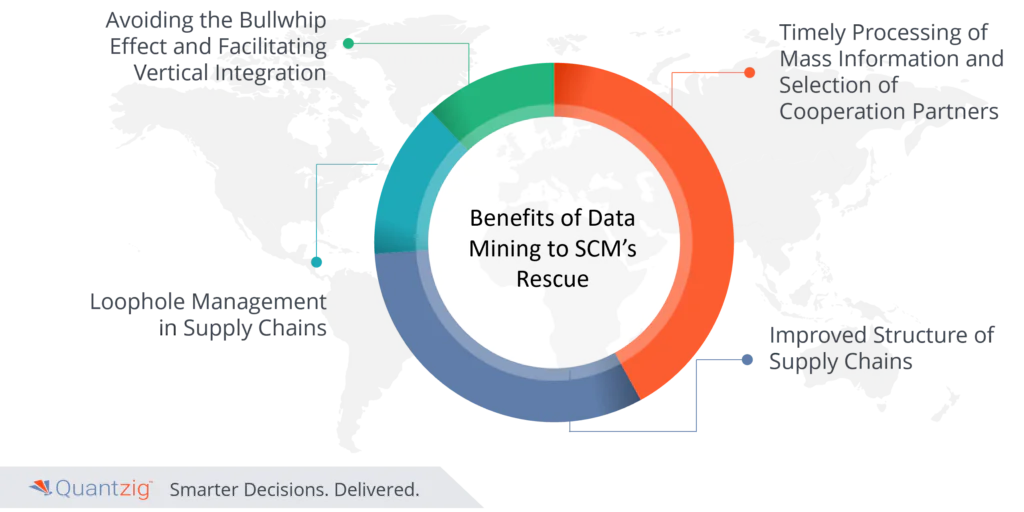

Benefits of Data Mining to SCM’s Rescue

In the supply chain management (SCM), the formidable challenge faced by managers is efficiently interpreting the technological and logistical implications of the vast reservoir of information. The integration of various business verticals within the supply chain further compounds this challenge. In an industry where swift turnaround time is paramount for gaining a competitive market share, making informed decisions in a timely manner becomes crucial. Here, we delve into the data mining technique, examples of data mining, benefits of data mining in supply chain management, a potent tool that not only helps avoid the ‘bullwhip effect’ but also facilitates seamless integration across various supply chain verticals.

- Avoiding the Bullwhip Effect: Data mining helps mitigate demand fluctuations by providing accurate demand forecasts, optimizing inventory levels, and ensuring smooth product flow through the supply chain.

- Facilitating Vertical Integration: By analyzing data across different business segments, data mining enables better decision-making, fostering collaboration and coordination within the supply chain for improved efficiency.

- Timely Data Processing: Data mining tools process large amounts of supply chain data in real-time, enabling prompt decision-making and increasing supply chain responsiveness.

- Partner Selection: Data mining evaluates partner performance and reliability, helping managers choose optimal partners to build stronger, more resilient supply chains.

- Loophole Management: Data mining identifies inefficiencies and vulnerabilities, allowing supply chain managers to address issues and improve resilience against disruptions.

- Improved Supply Chain Structure: By analyzing performance data and market trends, data mining optimizes distribution networks, warehouse management, and transportation, enhancing overall supply chain efficiency.

Experience the advantages firsthand by testing a customized complimentary pilot designed to address your specific requirements. Pilot studies are non-committal in nature.

Request a Free PilotEssential Data Mining Techniques for Logistics Professionals

Data mining is a crucial aspect of logistics, enabling professionals to extract valuable insights from large datasets and optimize supply chain operations. Here are four essential data mining techniques for logistics professionals:

1. Decision Trees

Decision trees are a fundamental data mining technique used to analyze and visualize data. They are particularly useful in logistics for identifying patterns and relationships between variables. By using decision trees, logistics professionals can optimize inventory management, streamline supply chain operations, and improve forecasting accuracy. Keywords: Decision Trees, Logistics, Inventory Management, Supply Chain Operations.

2. Clustering

Clustering is a data mining technique that groups similar data points together based on their characteristics. In logistics, clustering can be used to identify high-demand products, optimize warehouse layouts, and improve inventory allocation. Keywords: Clustering, Logistics, Inventory Allocation, Warehouse Layout.

3. Association Rule Mining

Association rule mining is a data mining technique that identifies relationships between different variables. In logistics, this technique can be used to identify patterns in customer purchasing behavior, optimize inventory levels, and improve supply chain efficiency. Keywords: Association Rule Mining, Logistics, Customer Purchasing Behavior, Inventory Levels.

4. Regression Analysis

Regression analysis is a data mining technique used to establish relationships between variables. In logistics, regression analysis can be used to forecast demand, optimize inventory levels, and improve supply chain efficiency. Keywords: Regression Analysis, Logistics, Demand Forecasting, Inventory Levels.

These four data mining techniques are essential for logistics professionals to optimize supply chain operations, improve forecasting accuracy, and enhance customer satisfaction. By leveraging these techniques, logistics professionals can make data-driven decisions and drive business growth.

The Future of Supply Chain Management: Data Mining and Predictive Analytics

In the era of big data, businesses have unprecedented access to vast amounts of information about their customers, market trends, and competitors. However, with great power comes great responsibility, and ethical considerations in marketing data mining are paramount. From segmentation analysis to decision-making, every step of the data mining process raises ethical questions about extraction, machine learning algorithms, and visualization techniques. It’s crucial for companies to navigate these ethical dilemmas carefully to ensure they uphold principles of fairness, transparency, and respect for privacy.

| Ethical Concern | Key Insights |

|---|---|

| Privacy Concerns in Data Extraction | Businesses must collect and use customer data ethically, ensuring transparency, consent, and strong security measures to protect sensitive information. |

| Fairness in Algorithmic Decision-Making | Algorithms should be designed to avoid bias and discrimination, ensuring fairness and transparency in customer segmentation and personalized marketing strategies. |

| Responsible Handling of Sensitive Data | Companies must comply with data protection regulations (e.g., GDPR) and establish secure data mining practices to protect sensitive customer and sales information. |

| Avoiding Manipulative Marketing | Data should not be used for exploitative marketing. Instead, businesses should focus on creating value-driven offers that build long-term customer trust and relationships. |

By addressing these ethical concerns, businesses can leverage data mining responsibly while fostering trust and sustainable growth.

Get started with your complimentary trial today and delve into our platform without any obligations. Explore our wide range of customized, consumption driven analytical solutions services built across the analytical maturity levels.

Start Your Free Trial nowConclusion

In conclusion, as supply chains continue to evolve at a rapid pace, the adoption of data mining supply chain management techniques becomes imperative for improved decision-making processes. From averting the bullwhip effect to fostering vertical integration and enhancing overall structure, data mining emerges as a strategic asset in the arsenal of supply chain managers. As the industry embraces the power of data-driven insights, it paves the way for more agile, resilient, and responsive supply chains, poised for success in the dynamic global market.